High Pressure Die Casting vs Gravity Die Casting Differences

Modern makers rely on various metal shaping approaches to achieve steady quality, and one known option is high pressure die casting vietnam. This process stands beside gravity-based shaping, and makers often compare both to decide which one suits their work. Each one handles molten metal differently, so the outcome changes. Makers pick one of these based on shape need, strength, cost, and output count. Here, we can see clear points that guide proper choices.

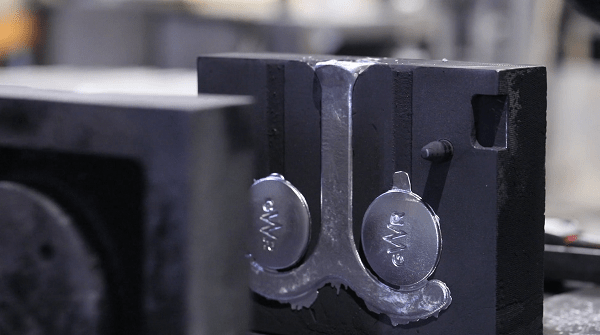

Metal Flow

Both processes handle molten metal through controlled flow that supports uniform filling and steady shapes with neat surfaces. This improves dependability across repeated cycles despite varied project needs across different works.

Tooling Steps

Tooling steps differ since one forces metal inside molds while the other uses simple drop flow. Each step influences strength levels and overall accuracy of the shaped piece produced for different uses.

Surface Clarity

Surface clarity depends on mold finish and metal pressure, which impact how neat the outer area looks after release. Makers choose based on visual needs and how smooth surfaces assist painting or coating.

Shape Flexibility

Shape flexibility helps create simple or complex pieces, which depend on mold strength and metal movement. This lets makers choose processes that match design goals and production expectations.

Table Comparison

| Feature | High Pressure Type | Gravity Based Type |

| Fill Force | Strong push | Natural fall |

| Mold Strength | High grade | Moderate grade |

| Surface Look | Very neat | Neat |

| Cycle Time | Fast | Steady |

| Complexity | Supports tricky forms | Suits simple forms |

Simple Guide

Selecting between both processes becomes easier when makers follow neat pointers that highlight strength, look, cost, and output needs.

• Choose metal shapes with clear edges that need pressure mold support

• Select simple forms that benefit from natural flow structure

• Pick steady cycles suitable for long work stretches

• Use strong molds when the structure’s firmness matters for tasks

• Plan output count wisely to reduce extra production spending

A proper choice supports smooth production flow by matching shaping needs with steady mold performance. Each approach stands useful when matched with the right design and output count. Makers compare strength, neatness, and spending needs before picking one, and this supports consistent pieces across long runs. When both shaping types are reviewed with careful checks, the right path becomes clear, which allows better planning across various works. This also shows how approaches like high pressure die casting vietnam support predictable results when matched with proper mold preparation and mindful checks.