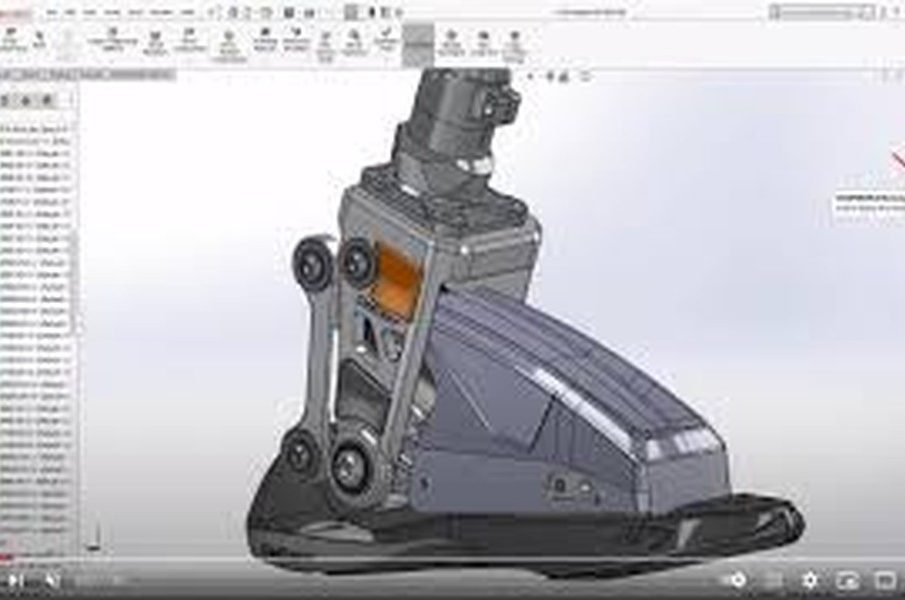

Aplikasi SolidWork for Product Design: From Concept to Manufacturing

In today’s competitive manufacturing environment, product design must be fast, accurate, and closely connected to production. This is where aplikasi SolidWork plays a critical role. Widely adopted by engineering teams and supported by SolidWorks Indonesia, this software enables companies to manage the entire product development process-from early concepts to manufacturing-ready designs-within a single digital platform.

Turning Ideas into Digital Concepts

Every successful product begins with an idea. Using sketch tools and parametric modeling, engineers can quickly transform rough concepts into detailed 3D models. With aplikasi SolidWork, designers can explore multiple design options without starting from scratch each time.

Design intent can be embedded into the model, allowing changes to be applied consistently across related features. This makes early-stage experimentation faster and more efficient, encouraging innovation while keeping development time under control.

Refining Designs with Virtual Testing

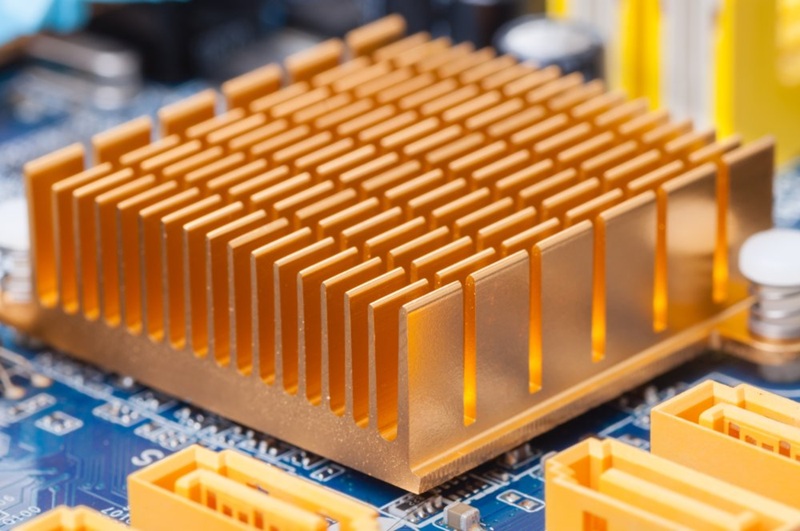

Before a product reaches the factory floor, it must be tested for performance and durability. Simulation tools within aplikasi SolidWork allow engineers to evaluate stress, deformation, motion, and thermal behavior under real-world conditions.

This virtual testing reduces dependence on physical prototypes and helps teams identify potential failures early. As a result, companies can improve product reliability while significantly lowering development costs.

Building Complete Assemblies and Production Logic

Product design rarely involves a single part. With assembly tools, engineers can combine multiple components into fully functional systems. Interference detection ensures that parts fit correctly, while motion analysis verifies that mechanisms operate as intended.

Manufacturing considerations can also be introduced at this stage. Designers can adjust tolerances, materials, and fastening methods to match real production processes, ensuring smoother transitions from engineering to manufacturing.

Preparing Designs for Manufacturing

One of the strongest advantages of aplikasi SolidWork is its ability to generate accurate manufacturing documentation directly from 3D models. Technical drawings, bills of materials, and flat patterns for sheet metal components can be produced automatically.

Through SolidWorks Indonesia, companies can also integrate design data with CNC programming, fabrication workflows, and quality control systems. This digital continuity minimizes errors caused by manual data transfer and improves overall production efficiency.

Conclusion: Connecting Creativity with Production Readiness

Product success depends on how well design and manufacturing are connected. By using aplikasi SolidWork, engineering teams gain a complete digital workflow that supports creativity, validation, and production planning within a single environment. Supported by local expertise from SolidWorks Indonesia, manufacturers can confidently move from concept to market with greater speed and consistency.